What is Die Cutting? Techniques, Applications, and Benefits

Die-cutting Packaging boxes are custom-designed product packaging boxes. Dies are used to achieve specific shapes, cuts, and designs. However, unlike simple or plain custom packaging, these boxes are tailored to fit perfectly. Before diving into the benefits, process, and types of die-cutting, first, explore what is die cutting. And how it can make your packaging distinctive from the other product boxes. However, with the ease of customization, You can easily add unique features like window cuts, handles, locking tabs, etc.

In this blog, we will try to elaborate on the die-cutting process and its versatile features that may help you make your product identical and stand out in the retail industry.

“Custom Die-Cut Packaging, Perfect Fit Every Time”

What is Die Cutting?

Die-cutting is a manufacturing process used to cut shapes, and trim materials like paper, plastic, fabric etc. In this process, a metal die is created. You can utilize this metal dies easily multiple times. By using a single die you can easily create same style boxes in bulk quantity.

What does a die cut mean? The Answer to this question is, a specialized tool made of metal-that has a sharp edge designed in a specific shape. When the die is pressed into the material, it cuts out the desired shape.

Multiple Types of Die-Cutting

There are three popular types of die-cutting which are common in practice. After having an overview of all three types you will be clearer about, what is die cutting.

- Flatbed Die-Cutting

- Rotary Die-Cutting

- Digital Die-Cutting

Flatbed Die-Cutting

A flat die is used in this process, the press used in this technique is flatbed. That’s why it is known as a flatbed. However, Suitable for thicker materials and intricate designs. You can spread your material on the flatbed and the die is applied with high pressure on the surface. However, this method of die-cutting is suitable for thicker materials and intricate designs.

Rotary Die-Cutting

It is clear from the name ‘Rotary’ that a rotational cylinder is involved in this method. Two main elements of this process, one is a cylindrical die and the second is a rotary press. However, this process is identical to the production of bulk and high-volume order preparation.

Digital Die-Cutting

This is a digital process to bring a packaging box into any particular shape or design. Computer-controlled devices are used and the cutting step is performed with the help of blades or layers. However, this is an advanced method of die-cutting. Unlike traditional die cutting, it does not require physical dies, providing greater flexibility and precision.

What Are Die-Cutting Packaging Boxes?

Die-cutting is essential in the packaging industry to design a custom packaging solution for your business and retail items. You can easily create impressive packaging boxes, labels, inserts, and different designs of locking flaps on your packaging boxes.

However, Die cut boxes are generated by using a die. An empress die cut machine is used to design impressive and highly appealing product boxes. A specialized metal tool with sharp edges that is fashioned to fit the intended pattern.

Sheets of material, such as cardboard, corrugated fiberboard, or plastic, are pressed using this die. The sharp edges of metal-dies create the required shape for your product packaging boxes.

Features of Die Cut Packaging Boxes

There are some amazing benefits of using custom-shaped packaging boxes for the presentation of your retail items in your local markets. There are a few matchless characteristics of choosing these versatile boxes for the progress of your business.

Custom Sizes and Shapes

Die cut packaging boxes may be produced in nearly any size or form, ensuring that the product fits perfectly. Better protection and a more polished look are guaranteed by doing this. You can easily design unique and distinctive shapes with the help of metal dies.

Customized Printing and Die cutting are an important aspect that can make your product stand out on the sales counters. Custom Packaging House offers some Innovative packaging designs for boxes like:

Although these are very few of them. You can easily design an alluring and fascinating-looking packaging box according to your product type and its dimensional sizes.

“Innovative Designs, Unmatched Durability”

Windows and Cutouts

A see-through window pane can easily added to your Custom Boxes wholesale. However, the visibility of packed content from the packaging boxes can easily convince your potential buyers.

Especially when you are dealing in Custom Food Boxes the window cuts can easily increase the temptation level for the packed stuff served in a creative packaging box with Windows.

Handles and Locking Flaps

Die-cut packaging can have locking tabs or flaps to secure the contents without the need for extra adhesives or tape, as well as handles for convenient handling. Packaging brands offer different packaging solutions with numerous kinds of flaps that can make your product boxes more secure, reliable, and eye-appealing,

- 1-2-3 Bottom Boxes

Design your Branding Elements

Die-cutting makes it possible to add distinctive branding components, logos, and elaborate designs that make items stand out on the shelf. A branded Product Box can make your product easily memorable as well as you can easily buy that particular product again in the future.

Benefits of Using Die-Cutting Packaging Boxes for Your Product’s Marketing

Several reasons can convince you to pick a die-cut wholesale Custom Packaging for your product’s branding and your business promotion. Take a look at a few pros of utilizing these stunning boxes with unique cuts for your product’s launch.

1. Improved Product Protection:

Custom-fit packaging guarantees that the item is securely enclosed, minimizing movement while in transit and offering superior defense against harm. You can easily choose the box designs also the addition of custom inserts inside the packaging can keep the product secure from damage and breakage during delivery.

2. Better Aesthetics:

Die-cut boxes improve the product’s overall presentation and attractiveness by giving it a polished, businesslike appearance. Customer prefers those products that look aesthetically appealing from rest of the competitor products.

3. Versatility:

Fits a variety of things, including food and drink, gadgets, and retail goods. With the help of customization, you can easily pick a suitable food box according to the edible item and its requirements for storage.

4. Cost-Effective:

Due to the effectiveness of the die-cutting process, die-cut boxes may prove to be more economical than normal boxes in bigger production runs. The ease of material selection and customized printing options make you comfortable in the selection of the best presentation boxes according to your budget plan.

5. Eco-Friendly Options:

In keeping with sustainable packaging techniques, die-cut boxes can be constructed from recyclable and biodegradable materials. The eco-safe packaging ensures that your product and your environment are safe from toxic and harmful gasses.

“Eco-Friendly Boxes, Expertly Crafted”

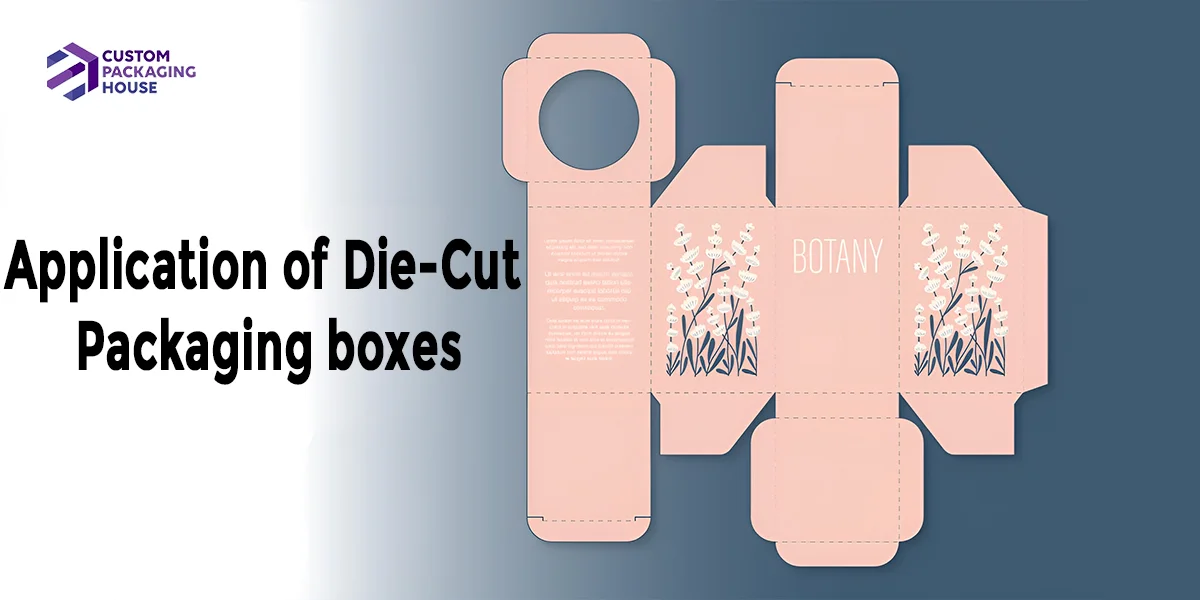

Application of Die-Cut Packaging boxes

The matchless characteristics of die-cutting technology make these boxes more popular in a few vast domains of life.

Retail Packaging

Retail packaging is perfect for goods like apparel, toys, electronics, cosmetics, and other items that need to stand out on the shelf. A stylish Custom display Box with unique cuts and windows can make your products easily noticeable to the targeted potential buyers.

For instance, you can easily add a see-through cut on your Lip gloss boxes to make their shades visible from the packaging. The visibility of the product can easily maintain the formation of the package and also assist the customers in making perfect buying decisions.

Food & Beverage Packaging

Frequently utilizing ventilation holes and windows, this type of packaging is used for products such as bakery goods, take-out meals, drinks, and specialized foods. You must observe that custom cake boxes or cake pop boxes always have a window on the facing flap to make the cake presentable.

E-commerce and Shipping

Offers a safe and expert packing option for items sent online, complete with personalized pockets and inserts for extra security. We offer different kinds of inserts that are particularly designed with die-cut technology.

- Foam Inserts

- Cardboard inserts

- PVC inserts

- Custom die-cut trays.

Gift Packaging

Ideal for crafting eye-catching and distinctive gift boxes for occasions such as weddings, festivals, and business presents. You can easily make your luxury rigid gift boxes more impressive by adding PVC window panes on their lids. Similarly, you can design a tailored-shaped box with a magnetic closer for a perfect gift presentation.

Pros and Cons of Die-Cutting in the Packaging Industry

Aspects |

Pros |

Cons |

| Efficiency and Speed |

|

|

| Versatility |

|

|

| Cost-Effectiveness |

|

|

| Design Flexibility |

|

|

| Precision and Consistency |

|

|

“Die-cutting transforms packaging from mere containers into bespoke works of art, perfectly tailored to protect and present your products.”

Hire Experts for Perfect Fit Packaging

Contact us to discuss your packaging needs and unlock the power of High-quality Custom shaped Packaging boxes. You can call us at 307 271 5170 or you can send us an email at sales@custompackaginghouse.com to get your INSTANT PRICE QUOTE.

Avail of our 30% discount offer on your order Place your RUSH ORDER today and get an amazing solution for the growth of your business.

Discover the power of precision with our die cut packaging boxes! Contact us today to create custom, eco-friendly, and eye-catching packaging solutions tailored to your needs.

Summing Up

Die cut packaging boxes offer a blend of functionality, protection, and aesthetic appeal, making them a popular choice for various industries. Their ability to be customized to specific product requirements ensures that they provide both practical benefits and a high level of visual impact.

Leave a Reply