Understanding Collation: What Does Collate Mean When Printing?

There are several Custom packaging manufacturers in the USA. Every brand offers its unique methods for printing and design. Printing plays a crucial role in designing Custom Packaging Boxes with logo. A well-designed and gracefully presented printed packaging box enhances the customer’s experience.

However, when you have to print multiple pages in a particular order you might come across the term “collate”.

What is the Meaning of Collate in Printing?

Collating is a popular concept in printing. When printing documents, especially multi-page ones, you might come across the option to “collate” the print job. This feature, while simple, is useful for organizing printed materials in the correct order.

However, this famous option is available in every printer setup. No matter what you are printing. Collating meaning is to arrange printing pages in a particular order. In this blog, we will discover what it means to collate. And when should you use this option?

Grammatical Meaning of Collate

In printing, collating means to arrange your printing page in a particular order. This is a definition of collating when printing. But in English, we define collate as:

Bring together different pieces of information. Some scholars describe the definition of collating as

“_to bring together different pieces of written information so that the similarities and differences can be seen”

Collated Printing

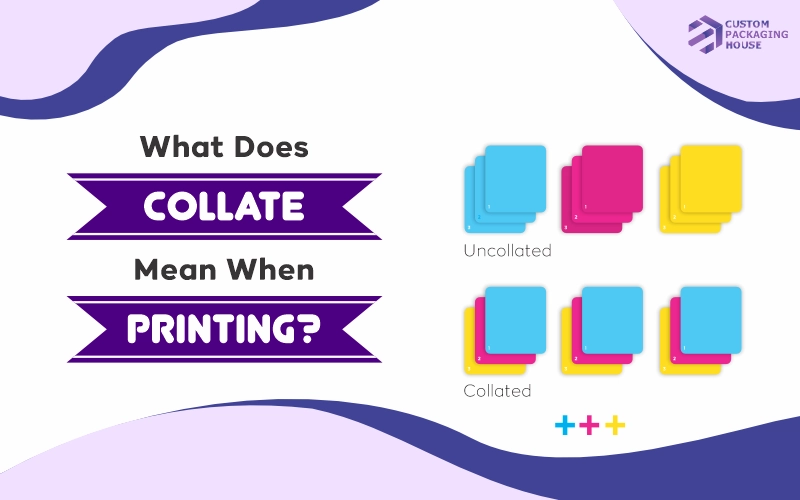

In the context of printing, to “collate” means to arrange the printed pages of a document in a specific order. This process ensures that the pages are printed in sequential order, creating complete sets of documents rather than grouping the same pages.

Difference between Collated and Uncollated Printing

You must understand the grammatical meanings of collated printing. Let’s take an example to understand this process more accurately.

For Example:

There is a document based on 6 pages and you have to print 5 copies to distribute among the students of grade 7.

Collated Printing Pattern

Let’s check the pattern of collated printing first.

- Set 1: Page 1, Page 2, Page 3, Page 4, Page 5, Page 6

- Set 2: Page 1, Page 2, Page 3, Page 4, Page 5, Page 6

- Set 3: Page 1, Page 2, Page 3, Page 4, Page 5, Page 6

- Set 4: Page 1, Page 2, Page 3, Page 4, Page 5, Page 6

- Set 5: Page 1, Page 2, Page 3, Page 4, Page 5, Page 6

Uncollated Printing Pattern

- Set 1: Page 1, Page 1, Page 1, Page 1, Page 1

- Set 2: Page 2, Page 2, Page 2, Page 2, Page 2

- Set 3: Page 3, Page 3, Page 3, Page 3, Page 3

- Set 4: Page 4, Page 4, Page 4, Page 4, Page 4

- Set 5: Page 5, Page 5, Page 5, Page 5, Page 5

- Set 6: Page 6, Page 6, Page 6, Page 6, Page 6

Analyzing different examples can help you understand this process deeply.

What Does “Collate” Mean in Packaging Printing?

Printing a document and printing custom boxes wholesale is a bit different. Collate printing in packaging acts differently compared to printing a document. Collation refers to organizing and arranging the different layers, prints, or components of the packaging in a specific, sequential order.

A product packaging box has multiple components:

- Front side

- Right side

- Left side

- Backside

- Top flap

- Bottom flap

When you choose collated printing all components of a box will print. After completion of all components of set a (box 1), the next box will start.

Collated Vs Uncollated Printing on Packaging

Features |

Collated |

Uncollated |

| Definition | Packaging components are printed and organized in sets, ready for immediate assembly. | Packaging components are printed in bulk, grouped by identical items, requiring manual sorting. |

| Packaging Component Arrangement | Ensures all parts of a packaging set are printed in sequence, simplifying assembly. | Prints all of the same components first (e.g., all outer boxes, then all inserts), requiring manual sorting. |

| Efficiency in Assembly | Highly efficient for multi-component packaging (e.g., subscription boxes, custom gift boxes) where parts need to be assembled quickly in the correct order. | Slower and more labor-intensive, as workers must manually sort and assemble packaging components |

| Application in Custom Packaging | Ideal for packaging with multiple elements, such as dividers, inserts, and product information cards, that need to be assembled in a particular sequence. | Suitable for identical or repetitive packaging components where order doesn’t matter during printing (e.g., bulk single-layer boxes). |

| Error Reduction | Reduces the likelihood of assembly mistakes since all components are pre-organized in the correct order. | Increases the potential for errors in assembly, as components must be manually arranged after printing. |

However, this comparison highlights the key differences between collated and uncollated printing in the context of packaging, helping you determine the best method based on the complexity of your packaging needs.

When to use Collating?

After understanding the methodology and process of collation, now the question is when to use collating and when we should avoid it. Understanding the distinction between these two options is crucial for optimizing efficiency and outcomes. Especially in scenarios where multi-page documents or multi-component packaging is involved.

Here are some common reasons to use collating.

- Printing of multiple pages in bulk quantities.

- Printed Labels and printed stickers in massive quantities.

- Preparing custom packaging with multiple layers or inserts that must be assembled in a specific order. Like round boxes, two-piece boxes, Drawer boxes, slipcase boxes, and different designs of Rigid boxes

- Producing educational materials, meeting handouts, or conference packs.

- Sometimes printer toner or ink is low you can go for this process to achieve at least a few complete boxes.

- If there are some additional processes like assembling and placing stickers, then you can finalize the boxes simultaneously.

- Similarly you need to bind the documents in that case you can easily do the binding in parallel

When to Avoid Collating Printing?

Although collate printing is a time saver. It is an effective printing approach but there are some particular scenarios when you should avoid using this printing pattern.

- When to print single-page documents, flyers, or posters.

- When you have to sort the components manually.

- If you are printing a single copy of a booklet.

How Collation Works in Packaging Printing?

Let’s break down the whole process into parts and explore the step-by-step process of printing custom packaging boxes with collate printing.

Step 1: Design your Box

The design and printing of packaging boxes consist of different parts. Like internal printing, external printing, inserts and dividers, etc. However, it maintains the consistency of colors and design. Each part needs to be printed and organized correctly to match the design.

Step 2: Printing the Components of the Boxes

After finalizing the design, the next step is to print every component of your custom box packaging. If your box consists of multiple parts then the collate function ensures that the prints are ordered correctly.

Step 3: Organized and arranged all pieces

Collation ensures that all parts and pieces are assembled properly. Whether it’s an outer sleeve, inserts, or additional elements like labels or stickers, collating guarantees that everything is in its place.

Step 4: Final Assembly

After collating, the packaging components are ready for final assembly. Colleton helps you in arranging correctly and effectively.

Benefits of Collating in Custom Packaging Boxes

Packaging is more than just a container. Especially when you are dealing with some brand. Your product packaging is a true representation of your brand that’s why you can ignore the appearance. Because it is the very first impression of your brand.

However, using collating in printing can help you in many different ways. Here are some key benefits of using this technique, and here they are:

Consistency and Accuracy

When you are printing something in bulk it is critical to maintain consistency. Collating helps in managing and accurately printing the same color all over the boxes.

Efficient Assembly

You can easily and effectively assemble the different parts of boxes. You don’t have to sort through different components manually. That’s why it saves time and reduces the chances of mistakes during assembly.

A Cost Saving Approach

An efficient approach can save you from making errors. However, collating helps avoid these costly mistakes by ensuring that every component is printed with the same potential.

Improved Customer Experience

A well-printed and organized packaging will surely improve the customer’s experience. It directly impacts the brand values.

Collating in Different Types of Packaging Boxes

This printing process is especially effective for those packaging boxes that have multiple components. Here are some special examples where collating is crucial.

Custom Gift Boxes

Custom Gift packaging boxes, especially those used by premium brands, often have multiple parts, including an outer box, internal inserts, and custom messaging.

Subscription Boxes

Subscription boxes frequently include various printed materials, such as product information cards, branded inserts, and promotional materials.

E-commerce Shipping Boxes

E-commerce brands rely heavily on branded shipping boxes/retail boxes to create a memorable unboxing experience. These boxes might have printed instructions, QR codes, or promotional inserts.

Folding Cartons

Custom Folding cartons often have intricate designs on the outside and inside. Collating ensures that the folding sequence and print placement are accurate.

How Can I Collate On A Printer?

Here are the directions to enable the collate option while printing.

- Open Your Document: Start by opening the document you want to print (e.g., Word, PDF, Excel).

- Go to Print Settings: Click on the “File” menu and select the “Print” option.

- Locate the Collate Option: In the print dialog box, find the “Collate” checkbox or icon (usually represented by two stacked sheets of paper with a number).

- Select the Number of Copies: Enter how many copies of the document you want to print.

- Enable Collating: Check the box next to “Collate” or select the appropriate icon for collated printing.

- Click Print: Once the collate option is enabled, click the “Print” button to start printing your collated documents.

Where to Find Fine Quality Printed Custom Boxes In the USA?

There are multiple custom packaging manufacturers in the USA. Custom Packaging House is one of the leading names in packaging suppliers where you can find quality printed boxes.

We offer RGB to CMYK printing, we also use the PMS system to generate exact and accurate shade for printing. You can contact us by email and get an INSTANT PRICE QUOTE. We are offering a Flat 30% discount on bulk orders.

Summary

In packaging printing, collating is an essential process that ensures that all parts of the Custom packaging box are printed, sorted, and organized in the correct sequence. Whether you’re printing custom gift boxes, subscription packaging, or e-commerce shipping boxes, collating helps streamline production, maintain accuracy, and improve overall efficiency.

Frequently Asked Questions:

Collating in printing refers to arranging the pages or components of a multi-page document or packaging in a specific, organized order, ensuring they print as complete sets.

Use collated printing when you're printing multi-page documents like reports, or manuals, or when packaging has multiple components that need to be assembled in sequence.

Collated printing organizes documents or packaging components in sequential sets, while uncollated printing groups identical pages or components together, requiring manual sorting.

Yes, collating works with double-sided (duplex) printing, ensuring the front and back pages are printed in the correct order.

No, collating only applies to multi-page documents or packaging with multiple parts. For single-page prints, collating isn't necessary.

Leave a Reply