Corrugated Flutes: The Backbone of Durable Packaging

We use cardboard in our daily routine. It would help if you observed a zigzag pattern hidden between the layers of flat cards. These wavy, arch-like structures add strength to the packaging boxes. They empower your custom cardboard packaging boxes by improving their durability. However, some brands also use these corrugated flutes to cushion products during shipping.

Understanding Corrugated Flutes: A Comprehensive Guide

When it comes to packaging, cardboard is the most popular material. In 2020, experts estimated that the world produced 66 million tons of cardboard. There is no limitation on size selection. From shipping boxes to retail packaging. These corrugated boxes offered durability, protection, and flexibility.

But what exactly makes these corrugated packaging boxes so effective?

The corrugated flutes are the actual strength of custom corrugated boxes. In this blog, we will discover different types of flutes. We will explore what they are. Why do they matter? And how they can impact your packaging industry.

What are Corrugated Flutes?

Custom corrugated cardboard packaging is based on three layers. An inside layer, an outside layer, and a middle layer. Fluting is the name of the middle layer. This flute is a wavy layer of paper, which is placed between the two liners.

Why do you need Corrugated Flutes?

The series of wavy structures provide rigidity and cushioning. These waves make corrugated boxes ideal for protecting goods during transportation. These flutes are available in different sizes and shapes. Every flute has its particular name and type. Their distinctive characteristics make them ideal for multiple applications.

Let’s explore different types of Flutes and their unique characteristics.

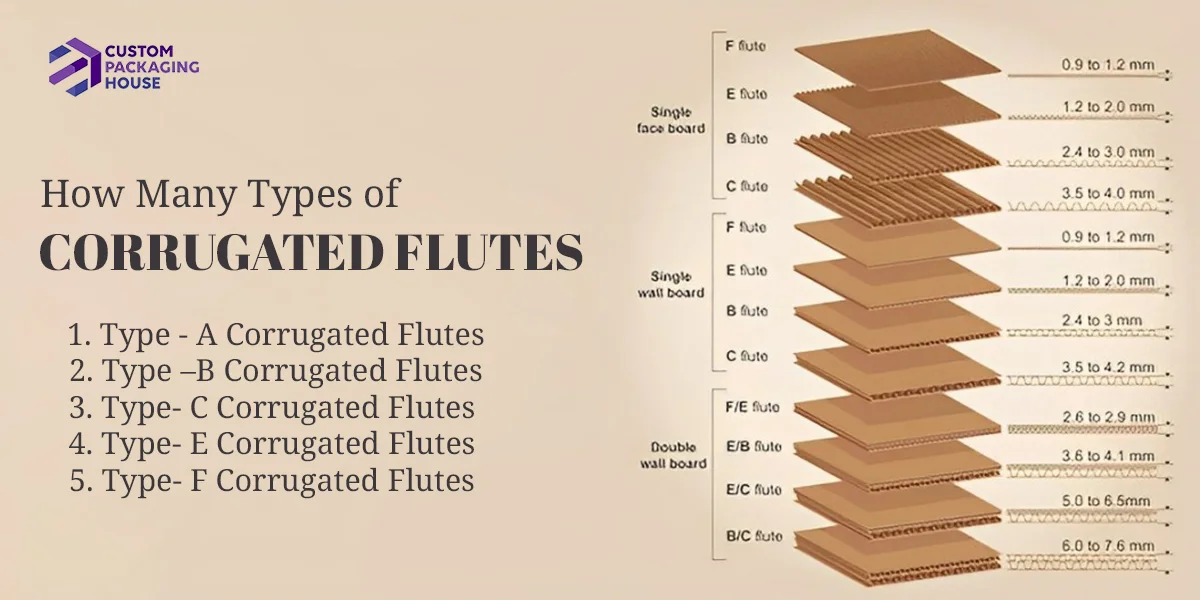

How Many Types of Corrugated Flutes?

There are five types of flutes. They are used in corrugated packaging boxes. They are listed below:

- Type – A Corrugated Flutes

- Type –B Corrugated Flutes

- Type- C Corrugated Flutes

- Type- E Corrugated Flutes

- Type- F Corrugated Flutes

Corrugated Cardboard Flutes are categorized according to different levels of thickness. A corrugated flute was discovered first. That’s why it is known as A-flute corrugated. Similarly, e and f flutes were introduced on last.

The corrugated flute size and thickness are identical. Every type has a particular fluting material and is classified by letters such as A, B, C, E, and F.

Type 1 – A Corrugated Flutes

This is the thickest type of flute. Due to dense waves, it offers the highest level of cushioning. The high compression strength makes it an ideal option for fragile items.

The thickness of the A flute corrugated is approximately 5mm equals 1/4 inch. You can find 36 flutes or waves per foot. The ultimate power of A-flute is perfect for heavy-duty shipping items. It can provide excellent cushioning for corrugated shipping boxes of delicate items.

Type 2 – B Corrugated Flutes

This is considered a middle-level thickness. It provides excellent puncture resistance and flat crush resistance. They are a common choice for marketing boxes.

The thickness of B corrugated Flute is 3.2 mm or 1/8 inch. There are 49 flutes per foot. They are thinner that’s why occupy less space. It is used for canned food packaging, different styles of display boxes, and various die-cut inserts.

Type 3 – C Corrugated Flutes

This is the second thick type of corrugated flute. This thicker type is feasible for general shipping corrugated fiberboard boxes and retail boxes. These boxes are perfect for stacking. The most common flute type provides a good printing surface for marketing.

The C flute thickness is between 3.5mm and 4mm. There are 38 to 40 flutes per foot. The c-flute corrugated cardboard is thicker than the b-flute. It means it is not easily compressible

Type 4 – E Corrugated Flutes

E-corrugated Flutes are best for printing. This e-flute corrugated cardboard is perfect for Custom printed cosmetic boxes. This is the second thinnest flute. These boxes are ideal for reducing storage space and production costs.

The thickness of the E-flute is approximately 1.6 mm or 1/6 inches. There are 90 flutes per foot. The thin surface makes them lightweight and ideal for high-quality printer printing. They are easily foldable that’s why feasible for folding cartons.

Type 5 – F Corrugated Flutes

This is the thinnest type of corrugated flutes. The ultra-thin and smooth surface generates fine-quality printing results. You can easily place it inside the high-resolution printers. These boxes are ideal for the countertop display boxes.

The thickness of the f-corrugated flute is about 0.8mm or 1/32 inches. It can 128 flutes per foot. They are perfect for small retail items.

Corrugated cardboard flute chart

For a better analysis of different thickness levels and sizes let’s make a corrugated cardboard flute chart for a quick overview.

Flute Type |

Thickness |

Flutes per foot |

Common use |

| A-flute | 5mm or 1/4 inch | 36 | Heavy-duty shipping, fragile items |

| B-flute | 3.2 mm or 1/8 inch | 49 | Canned goods, die-cut inserts, displays |

| C –flute | 3.5mm to 4mm | 38 to 40 | General shipping, retail packaging |

| F- flute | 1.6 mm or 1/6 inches | 90 | High-quality print packaging, folding cartons |

| E- flute | 0.8mm or 1/32 inches | 128 | Small retail packaging, point-of-purchase displays |

This corrugated thickness chart shows flute thicknesses and their uses.

Why Flutes Size Matter?

The flute size i.e. flute per foot depends on the specific need of Custom Packaging Boxes. Custom Packaging with larger flutes like A and C offers more cushioning. That’s why they are considered ideal for the shipment of fragile items.

On the other side if you want better printing instead of high-level security. Go for printed custom packaging with smooth surfaces like E and F. They are ideal when the presentation is key.

The spacing between flutes also matters. It plays a role in the overall strength of the corrugated cardboard box. For instance, B-flute, a higher number of flutes per foot, provides better resistance to crushing forces.

However, the thicker flute has more weight compared to the thinner one. That’s why every cardboard weight varies from others. It depends on the number of flutes and box size.

Which Factors You Need to Consider with Corrugated Flutes?

Along with corrugated flutes, there are some other factors, you need to consider when choosing your Custom Corrugated Packaging Boxes. These three important factors are the following:

- Board Type

- Box Style

- Printing Type

1. Board Types

Corrugated Packaging Boxes Wholesale are made with a combination of liners and flutes to create various board types. These liners and flutes decide the strength level of corrugated packaging. Let’s explore different kinds of boards that are commonly used in corrugated Boxes in the USA.

Single Face Board

One layer of flute glues to a one-liner or flat sheet. It is primarily used for cushioning and protective wrapping of the products. It can be used to wrap delicate and fragile items. It provides elementary-level protection.

Single Wall Board (Double Face)

One layer of fluted surface is placed between the pair of flat liners. This is the most common type of corrugated packaging box. They are popular for shipping and retail boxes.

Double Wall Board

Two layers of flutes are placed between the pair of flat surfaces, each separated by a liner. These boxes are ideal for heavy-duty packaging. They have greater strength and durability than single-wall boards.

Triple Wall Board

From the name of the board type, it is clear that they have three layers of flutes. Each is separated by a liner, with an additional liner on the outside. Suitable for heavy machinery like large electronics. Superior strength and maximum protection are often used as an alternative to wooden crates. Increasing the number of flutes will raise cardboard cost and strength.

2. Box Style

Some particular box styles are exclusively designed in corrugated style. People thought that corrugated packaging boxes could be made only in square, rectangular shape. But you can mold corrugated flutes into different shapes into boxes.

Mailer Boxes: these boxes are ideal for shipment and delivery. Most e-commerce brands utilize these boxes to deliver their products worldwide. These are also ideal for subscription and PR boxes. They are highly customized able and effective to enhance your unboxing experience.

Shipping Boxes: As the name describes they are designed exclusively for the shipping purpose. The durability and strength of these boxes ensure that your products will be delivered safely to the destination.

Die Cut Boxes: These boxes can be made in any particular shape. Custom hexagon boxes wholesale, Triangle-shaped boxes, and different gift boxes with a nice presentation can also made in die-cut style.

3. Printing Type

Custom Packaging Manufacturer offers different printing options for your printed corrugated boxes. When it comes to printing on corrugated boxes, the choice of printing method depends on the design requirements, budget, and the intended use of the packaging.

Digital, screen, offset, lithography, flexography, CMYK and RGB. Lithography is ideal for corrugated boxes in bulk. Whereas, Flexographic printing uses flexible relief plates to transfer ink onto the corrugated surface. It is the most widely used printing method for printed corrugated boxes wholesale due to its cost-effectiveness and versatility.

Wrapping up on corrugated Flutes

Now after exploring everything about the corrugated flutes. You can easily understand which flute type is perfect for your products. Whether you packaging fragile items for shipping or designing eye-catching retail displays, choosing the right corrugated flute can make all the difference. If you have something else in your mind. Feel free to contact Custom Packaging House. We are offering a Flat 30% discount on bulk orders.

Frequently Asked Questions:

Corrugated flutes are wave-like, arch-shaped paper layers sandwiched between flat liners in corrugated cardboard. They provide strength, cushioning, and durability to the packaging, protecting items during shipping and handling.

Corrugated flutes are categorized by size and thickness, with common types including A, B, C, E, and F-flutes. A-flute is the thickest, offering the most cushioning, while the F-flute is thinner and ideal for high-quality printing.

Choosing the right flute type depends on factors like product weight, fragility, and packaging needs. For example, A-flute is suitable for heavy, fragile items, while E-flute is ideal for retail packaging with detailed printing.

Smaller flutes, like E and F-flutes, provide a smoother surface, which is better suited for high-quality printing and branding. This makes them ideal for retail packaging where appearance and design are crucial.

Yes, corrugated flutes are recyclable. They are made from paper-based materials and can be easily processed into new products, making them an environmentally friendly packaging option.

Leave a Reply