5 Reasons Why Cardboard Boxes Are So Expensive?

E-commerce businesses are booming these days. Custom Cardboard Packaging Boxes are essential for e-businesses and consumers, playing a crucial role in packaging, shipping, and storage. However, Cardboard boxes have become more expensive due to a combination of factors.

Most suppliers and dealers use this sturdy stuff to package their business items. People have become more conscious about the eco-system. And it is a core reason for choosing this expensive stock because it is eco-safe and 100% recyclable.

In this blog post, we’ll explore five key reasons why cardboard packaging boxes have become so expensive. But first, discover what Cardboard is.

What Are Cardboard Boxes?

Cardboard is a strong material used in making rectangular boxes. However, this thick, durable paper-based material is ideal for the Packaging industry. These boxes can be shaped and customized according to the customer’s demand.

Cardboard-The History

Back in the 15th century, cardboard was invented in China. If we talk about the history of this masterpiece. But you can’t fold them. Scottish-born Robert Gair invented the pre-cut cardboard box in 1890. Later on, these flat pieces folded into shapes.

Cardboard- 100% Natural Ingredients

Eco-safe cardboard is made from fiber from plants and trees. However, the pulp is taken from natural sources. That’s why they are completely harmless to the ecosystem. These cardboard packaging boxes can be created by recycling wood chips and shavings.

“Strong, Sustainable, Secure – Cardboard That Cares”

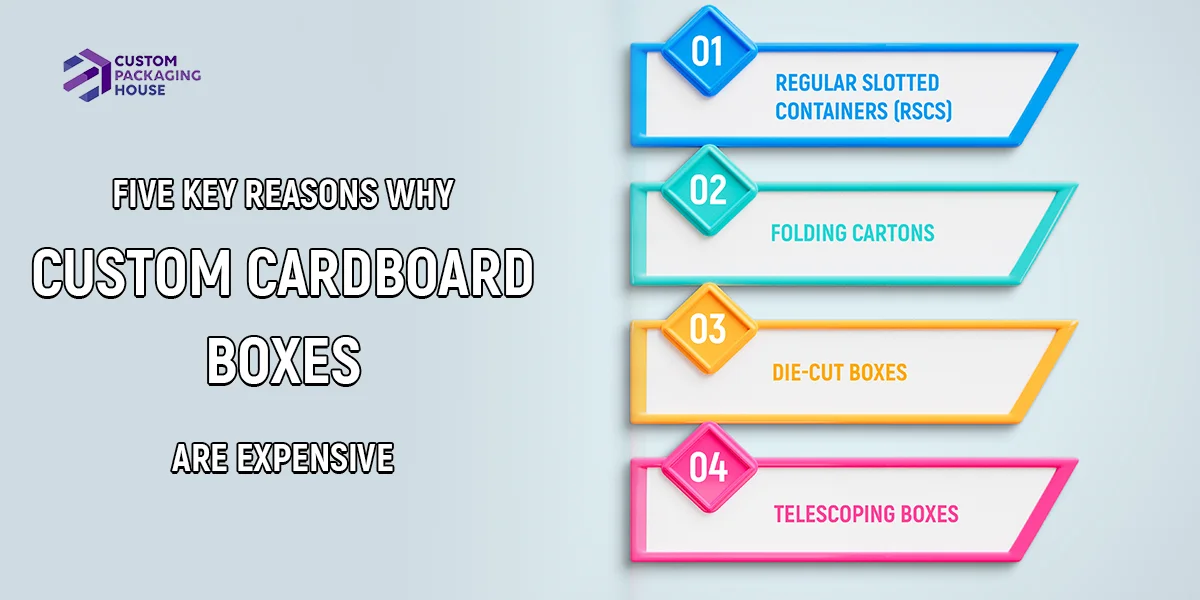

Five Key Reasons Why Custom Cardboard Boxes Are Expensive

The price of cardboard has increased 2X as compared to early 2000. The inspiring and amazing characteristics of these boxes have won people’s hearts. The versatility and robustness of boxes make them an ideal choice in packaging and business.

However, the rapid increase in pricing has made everyone worried about these packaging boxes. In the past people preferred to go market on their own. After the pandemic session of COVI-19 online shopping became a trend.

Custom Cardboard Packaging Boxes are ideal for ensuring damage-free delivery and the ultimate safety of products. These are some prominent reasons behind the cost increase but there are some other causes too. Let’s explore them.

1. Rapidly Increasing Customer’s Demand

The skyrocketed demand for Cardboard is one of the top reasons for its high price. However, more online shopping means more packaging, and this surge in demand has driven up prices.

In today’s fast-paced world, people have no time to go to market and go shopping. That’s why they prefer to place their orders online. And every online order needs a box for delivery.

According to an estimation, there are 268 million online shoppers in the USA. It is estimated that the e-commerce market will hit sales of USD 58.74 trillion by the end of 2028. This growth is a phenomenon. So when millions of orders are placed, this high demand will push the prices upward.

2. Raising the Cost of Raw Material

The product price will be high if its raw material is expensive. The increase in the cost of raw materials will ultimately impact the product cost. The price of raw materials has gone up, especially wood pulp, used to make cardboard.

However, there are multiple reasons for the high price of raw materials. I.e. laws about the environment, worries about deforestation, and the scarcity of resources that are supplied responsibly.

Custom Packaging made with Cardboard is a sustainable option. As sustainable sourcing becomes more critical, the price of responsibly harvested wood pulp has increased. Additionally, the overall scarcity of raw materials has made it more expensive to produce cardboard, driving up prices for the end product.

“Cardboard Crafted for a Sustainable Future”

3. Cost of Production

Custom Printed Cardboard Boxes are available in different shapes, styles, and designs. However, you can easily do printing on this reliable stock. However, there are multiple methods available for printing on these printed packaging boxes.

The cost of printed cardboard boxes varies according to the printing method and its printing materials. Moreover, the cost of production also involves some additional charges like:

- Cutting

- Printing and designing

- Assembling/ Shaping/ set up cost

- Transportation/shipping cost

4. Recycling Cost

As you know Printed Cardboard Boxes Wholesale are made with eco-safe material that’s why recycling cost is also included. This process itself is costly and has become more expensive. The cost of collecting, sorting, and processing recycled cardboard can be significant, especially with stricter environmental regulations.

However, the trend of recycling has increased exponentially in 2024. From a rough estimation, the recycling rate for cardboard in the US reached nearly 97% in 2019.

5. Transportation Cost

Transportation costs have surged due to higher fuel prices and a shortage of truck drivers. These transportation costs affect every stage of the supply chain, from delivering raw materials to shipping finished boxes to businesses and consumers. Moreover, the weight of Customized Cardboard Boxes impacts your actual production cost.

“Cardboard Solutions for a Greener Tomorrow”

Explore Different Types of Cardboards

There are various types of cardboard available in the market. However, every type has its particular price quote. Personalized Cardboard boxes with different laminations and printing methods vary concerning price.

Regular Slotted Containers (RSCs)

The most common type is where all flaps are the same length and meet in the center when closed. However, you can design them with several modifications. You can choose a tuck-end box style, or you can also choose a sealed end box for your wholesale Custom Packaging.

Folding Cartons

Used for lighter products, these are often found in retail packaging and can be folded flat when not in use. They are effective in branding by choosing versatile Printed Packaging Boxes.

Die-Cut Boxes

Custom-designed to fit specific products, these Die-cut boxes are cut from a single sheet of cardboard and are often used for unique shapes or sizes. Whether you are designing Custom Food Packaging Boxes or need luxury rigid gift boxes this unique cardboard packaging is perfect for your business.

Telescoping Boxes

Consists of a separate top and bottom that slide over each other, offering adjustable height for varied product sizes. Two-piece boxes are one of the popular packaging designs. You can easily create a long-lasting impression by presenting your products in stylish custom gift packaging boxes.

“Boxed with Purpose, Delivered with Care”

Some Affordable Alternatives of Expensive Cardboard

Printed Cardboard Boxes Wholesale are sturdy, rectangular containers made primarily from thick, durable paper-based materials. They are widely used for packaging, shipping, storage, and moving goods. However, if you’re looking for cheaper alternatives to cardboard, here are some options that can serve similar purposes for packaging, storage, or moving:

- Plastic Containers

- Reusable Fabric Bags

- Wooden crates

- Shrink/ plastic wrap

- Bubble wrap

- Padded envelops

- Kraft paper Bags

- Kraft Paper Boxes

- Mylar Packaging Bags

Each of these alternatives has its strengths and weaknesses, so the best option will depend on your specific needs, such as the type of items you’re packaging, the distance they will travel, and your budget.

Why Cardboard is A Matchless Packaging?

There are a lot of marketing benefits of using printed cardboard boxes. That’s why people are willing to pay for such an expensive packaging option. Versatility and customization make these boxes matchless in the competitive retail market. However, these cardboard boxes are compatible enough to deal with heavy and large products. All of these characteristics make cardboard an effective material to choose for numerous products across a range of categories.

Whether you explore food packaging or you need stylish custom cigarette boxes these boxes have the potential to stand out in the competitive retail market without demolding the cigarettes inside the pack.

What Can Replace Cardboard?

The future of packaging is evolving as companies seek more sustainable, efficient, and cost-effective alternatives to cardboard. While it’s unlikely that a single material will entirely replace cardboard, several innovative alternatives are emerging that could serve as replacements or complements in various applications:

- Mushroom based Packaging

- Corrugated Bubble wrap

- Degradable Packaging Peanuts

- Seaweed Packaging

All of these are eco-safe alternatives to Cardboard Packaging Boxes. While cardboard is likely to remain a staple for many applications, these emerging materials offer exciting possibilities for more sustainable and efficient packaging solutions.

However, as technology advances and environmental concerns continue to drive innovation, the packaging industry will likely see a gradual shift toward these alternatives.

“Where Durability Meets Eco-Friendly Innovation”

Where Can I Buy Cardboard?

There are various custom packaging manufacturers in the USA. There are many retailers, and online suppliers like Amazon, eBay, Ali Express, etc. All these online plate forms are offering these sturdy printed boxes wholesale. Custom Packaging House is one of the leading packaging brands. Where you can easily get cardboard packaging with all possible customization options. These boxes offer the most suitable option for shipping your products

Their durable Cardboard boxes can add more potential to your business items by making them highly appealing and fascinating.

You can get your INSTANT PRICE QUOTE by calling us at ( 307 ) 271 5170. You can also place your RUSH ORDERS by sending us an email at sales@custompackaginghouse.com

Our Printed Custom Cardboard boxes are ideal for packaging gifts, food items, and several luxury products like perfumes, watches, jewelry, etc. Don’t waste your time. Place your order today and get a Flat 30% discount on bulk orders.

Wrapping Up

The rising cost of cardboard boxes is a result of a complex interplay of factors, including surging demand, supply chain disruptions, higher raw material costs, increased energy and transportation expenses, and labor shortages.

While these challenges are likely to persist in the near term, understanding the reasons behind the price increase can help businesses and consumers make more informed decisions when it comes to packaging and shipping.

Leave a Reply