What is Embossing and Debossing in Packaging?

Presentable packaging is crucial for your business’s success. Packaging is not only about protecting your content; it’s also about creating a memorable and appealing experience. Packaging companies offer various kinds of add-on options. Embossing and debossing are famous techniques that enhance your product’s presentation.

They can add depth, texture, and 3-D effects, and reinforce brand identity. Your product stands out by adding embossing and debossing in the custom packaging. Let’s explore what these methods are. And how you can use them efficiently.

Whether you are working on business cards, invitations, gift packaging, or book covers. They can help you with branding and promotion. Knowledge of embossing and debossing can help you choose the right technique. That brings your vision to life. Let’s explore a little deeper and understand the main difference between them.

What is Embossing?

Embossing is a method that can add a raised effect on the surface. Yet, in this process, a metal die made of brass material like dies used in die-cutting. Press the metal die with pressure. And creates a raised impression on the surface.

You can easily feel a 3-D effect. That adds a luxurious and professional touch to your packaging. The metal die pushes the texture upward on the surface. That is visible and feels with fingers.

Application of Embossing

You can use embossing in different ways.

Business cards

Embossing can make a company logo, name, and other elements visible. It can make your cards elegant and sophisticated. A high-end-looking business card is a true representation of your class and style.

Invitations

Embossed textures and monograms add elegance to your invitations. You can emboss the company name on a co-operate invitation. You can carve the bride and groom’s names onto a wedding invitation.

Packaging Boxes

The embossing on the packaging adds a layer of sophistication and refinement. Engraved logos or brand names on packaging directly impact the product’s value. You can make custom gift boxes more exciting by embossing the presenter’s name.

“Elevate Your Brand with Every Touch.”

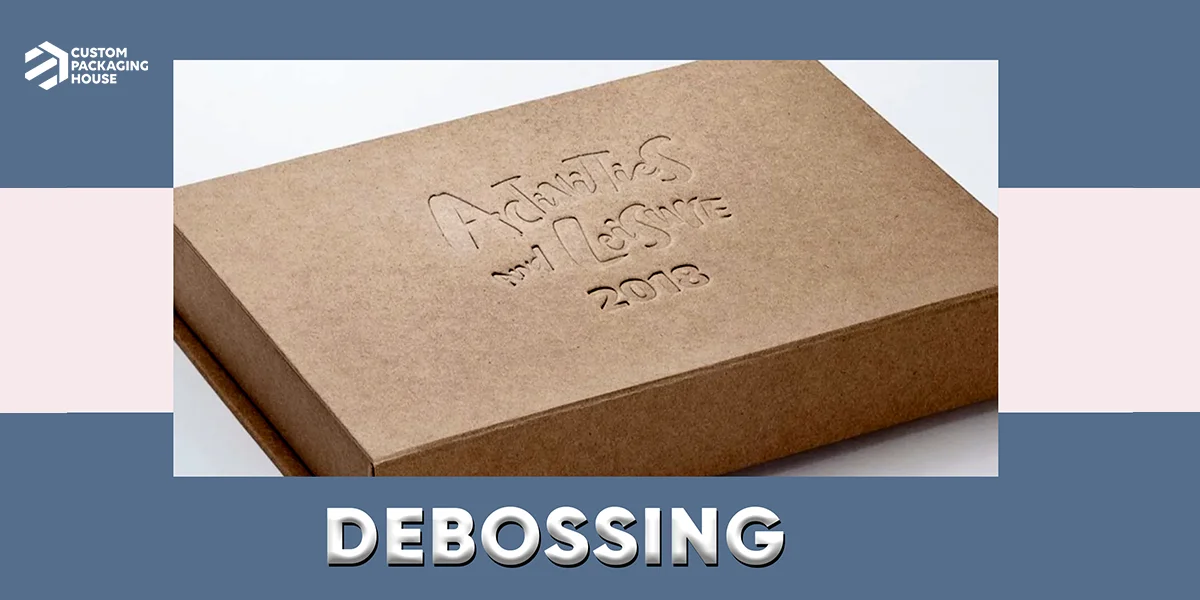

What is Debossing?

Debossing is the opposite of embossing. Instead of raising the design, debossing presses the design into the packaging. It creates an indent effect. This is also done with metal dies. Yet, the result is a design that depresses the surface.

Application of Debossing

You can use debossing in different ways. Here are a few of them.

Book Covers

Debossed titles and author’s names add a classic and elegant touch to your books Designers create custom book covers to provide a protective shield for your books. Gold foiled effect with debossing can make your book elegant and presentable.

Leather Goods

Leather goods often feature debossing techniques. Most brands deboss their logo and brand names on their leather items like wallets, belts, and bags. The recessed design adds a subtle, refined touch.

Co-operate Branding

Debossing is perfect for branding. But, it highlights the important data. You can print logos and other branding elements to your office file covers and folders.

“Depth and Dimension, Redefined.”

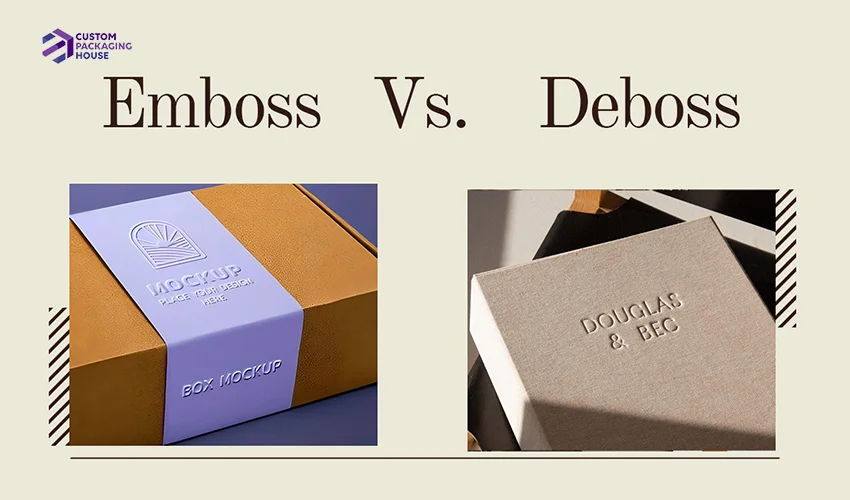

Embossing Vs Debossing

People found embossing and debossing a bit confusing. However, it is a bit harder for them to decide which one to choose for their Custom Boxes Wholesale. Let’s do a comparative analysis of both of them.

Aspects |

Embossing |

Debossing |

| Visual Effects | Creates a raised design that stands out visually. | Create a recessed design, giving a sunken effect. |

| Tactile Experience | The raised design offers a prominent tactile feel. | The Recessed design provides a subtle, indented feel |

| Material Suitability | Suitable for thicker, rigid materials. | Versatile across various materials, including leather and paper. |

| Design Perception | Conveys a premium, high-end look. | Conveys an elegant, understated aesthetic. |

| Application | Perfect for highlighting key elements like logos. | Best for creating refined, sophisticated designs |

These are a few major differences between embossing and debossing. You can easily decide on both techniques. Rigid Packaging boxes are popular for Luxury Rigid gift packaging. The high-end luxurious presentation of these boxes ensures ultimate safety with style.

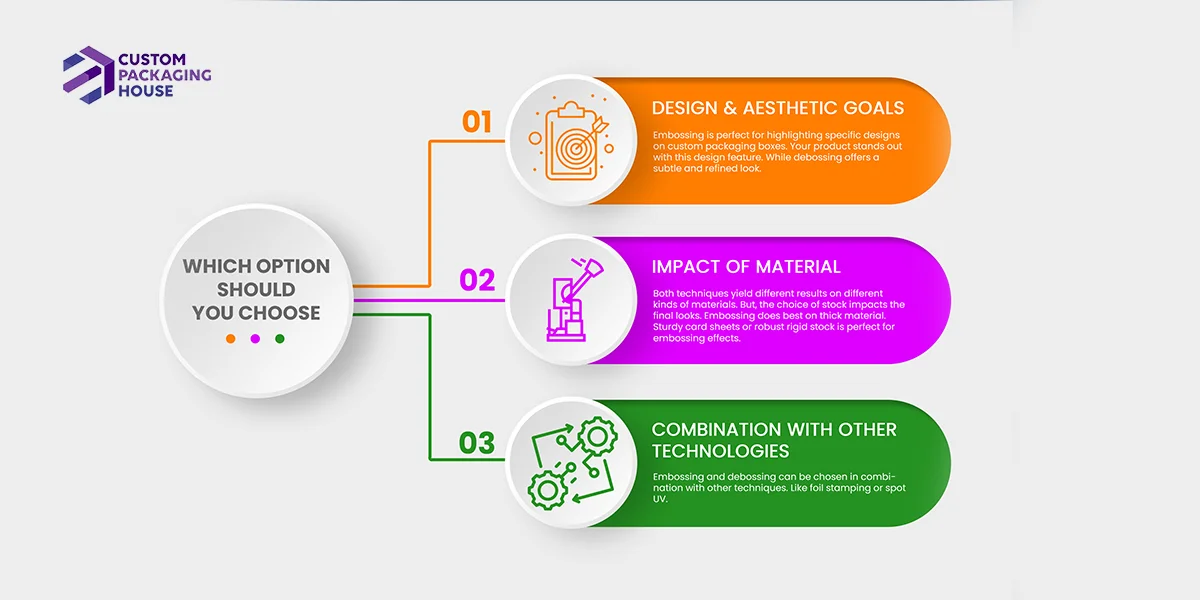

Which option should you choose: embossing or debossing?

While deciding between embossing and debossing take care of the following factors.

Design and Aesthetic Goals

Embossing is perfect for highlighting specific designs on custom packaging boxes. Your product stands out with this design feature. While debossing offers a subtle and refined look.

Impact of Material

Both techniques yield different results on different kinds of materials. But, the choice of stock impacts the final looks. Embossing does best on thick material. Sturdy card sheets or robust rigid stock is perfect for embossing effects. Custom perfume boxes or luxury gift boxes look more elegant with embossing. Whereas, debossing came up nice on various surfaces, such as leather, fabric, etc.

Combination with other Technologies

Embossing and debossing can be chosen in combination with other techniques. Like foil stamping or spot UV. For instance, you add foiling on the boundaries of the raised section. It can make your custom cosmetic boxes wholesale shiny and striking.

“Crafted for a Lasting Impact.”

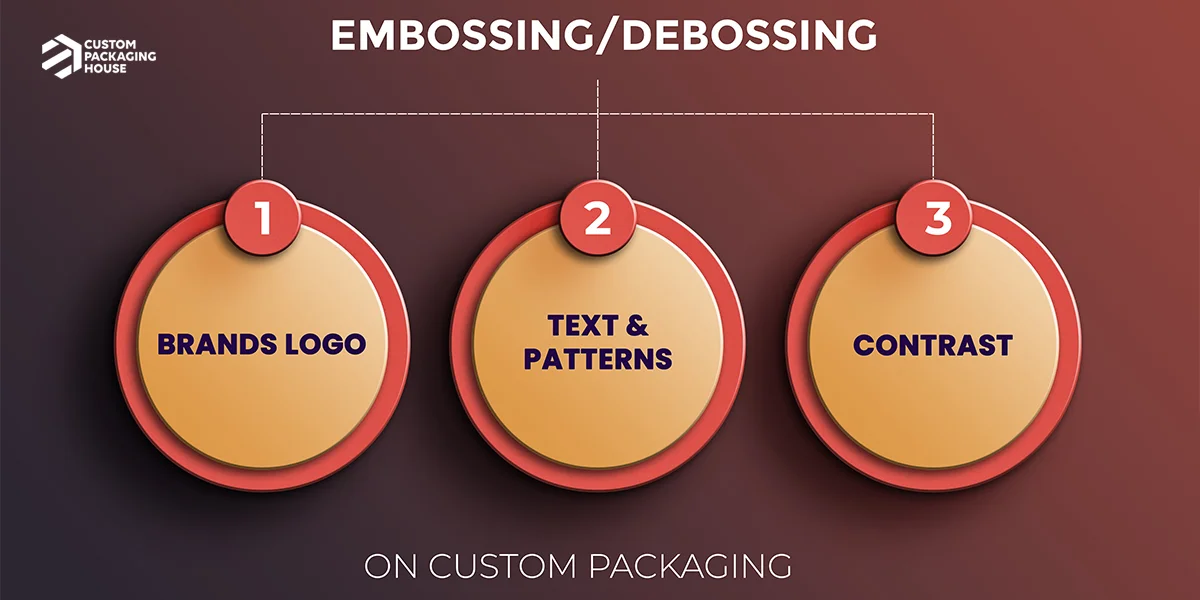

Application of Embossing/Debossing on Custom Packaging

The raised impact of embossing is perfect for giving an elegant look to the packaging. There are some particular areas on packaging where you can apply embossing.

Brands Logo

The logo engraved box looks fascinating and stands out. This is especially effective for luxury products. You can leave a lasting impression on targeted customers. An embossed logo helps the customers in memorizing.

Text and Patterns

Some brands and suppliers select textured boxes for their products. However, Embossing can highlight specific text, such as product names or taglines. A luxury apparel box or a cooperative gift box can be designed with an embossed pattern.

Contrast

Debossing has a deep impact. It creates a contrast between the smooth surface and the recessed area. However, this can generate a tactile experience that engages consumers.

A booklet-style box with a magnetic closure and a debossed logo can give a luxury feel. Your product becomes more elegant and why you present them gracefully.

“Textured Elegance, Unmatched.”

What is the process behind the Embossing and Debossing?

The process of embossing and debossing involves several steps. These steps are based on design creation to produce the final results.

Step 1: Design Creation

The first step is finalizing the design or pattern. The design is created in vector format. Select either you want emboss or deboss effect.

Step 2: Die Production

Once the design is final, then create the die. This die is made of metal like brass. A custom-made die is designed for every project. This die is used to press with pressure on the material.

Step 3: Pressing

In the case of embossing, the material is placed between the die and a counter die. For debossing, it is placed between the die and the flat surface. Yet, in both cases, pressure is applied to transfer design on the surface.

Step 4: Final touches or finishing

After embossing or debossing the final touch is trimming or folding.

“Make Your Mark with Tactile Precision.”

Where to get custom boxes with embossed effects?

Suppliers and wholesalers feel confused. There are dozens of packaging manufacturers in the USA. Custom Packaging House offers premium-quality luxury solutions with embossing and debossing. You can choose any of them at affordable prices.

Get your Custom boxes wholesale with an embossed logo or debossed texture at your doorstep. Call us at (307) 271 5170 and place your RUSH ORDER now. You can also get your INSTANT PRICE QUOTE by sending us an email at sales@custompackaginghouse.com

Place your order now and enjoy a flat 30% discount on your wholesale custom-printed boxes.

Summing Up

Embossing and debossing are powerful techniques in the packaging industry, offering a way to add depth, texture, and sophistication to product packaging.

By understanding the differences between these methods and their applications, brands can make informed decisions that enhance their packaging and strengthen their market presence.

Leave a Reply